For this post i specifically focused on remaking my hinge because it totally changed shape. Now the other thing is that each piece that is in progress in metal is definitively subject to change as my jewellery project continues which is also why im choosing to do a lot of modelling after parts are complete.

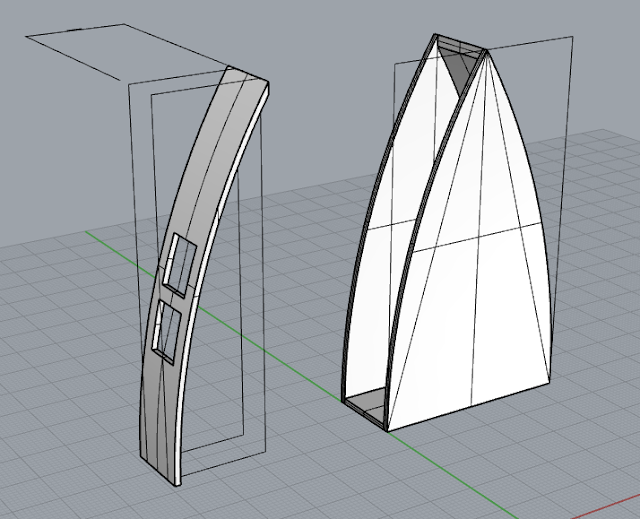

The other thing i was able to do was create a design that i could saw out in accordance to the design of the metal which is this one right here

In creating this it is much easier with a set of of lines (Trim) and a fillet tool than trying to create it in real life on a piece of paper and getting it correct.

The next issue that was encountered was how to create a shape that you could measure to create the 3D model and well its called tape and then cut it to the size of the plate of metal which is how the boxes on the sides of of the abovve shape which i really struggled with without some help.

The boxes had to be vertical and then using a function called flow and a little bit of orientation issues it finally worked and i was able to get that part of the design

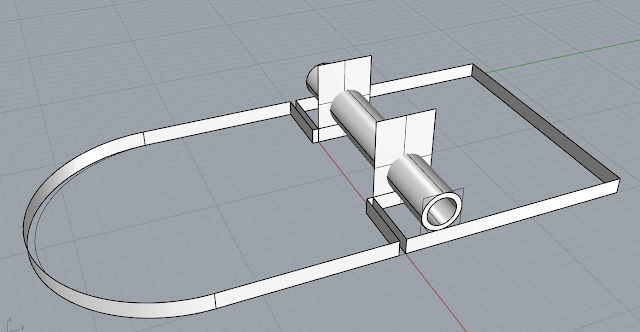

This is the redone hinge in relation to the real one

I also remembered some of the commands from 2 years ago and you can make the hinge rotate perfectly its so beautiful to see in CAD.

And then the last thing i worked on was the gears. There are 2 different sizes but they are very close however they are from a broken drill so they move incredibly well so making sure to design them similarly in rhino was slightly difficult and took a couple trouble shoots to get them as close to the originals.

So this above is the failed design and the setup for it was incorrect as the Boolean did not complete for me because part of the item was improperly shaped and could not be completed by the operation so i had to go back to the basic shape and completely redo the extruded curves

And Success. looks nice and its all one poly surface now it has to go into its proper spot which is the squares in the side of the hollow box.

No comments:

Post a Comment